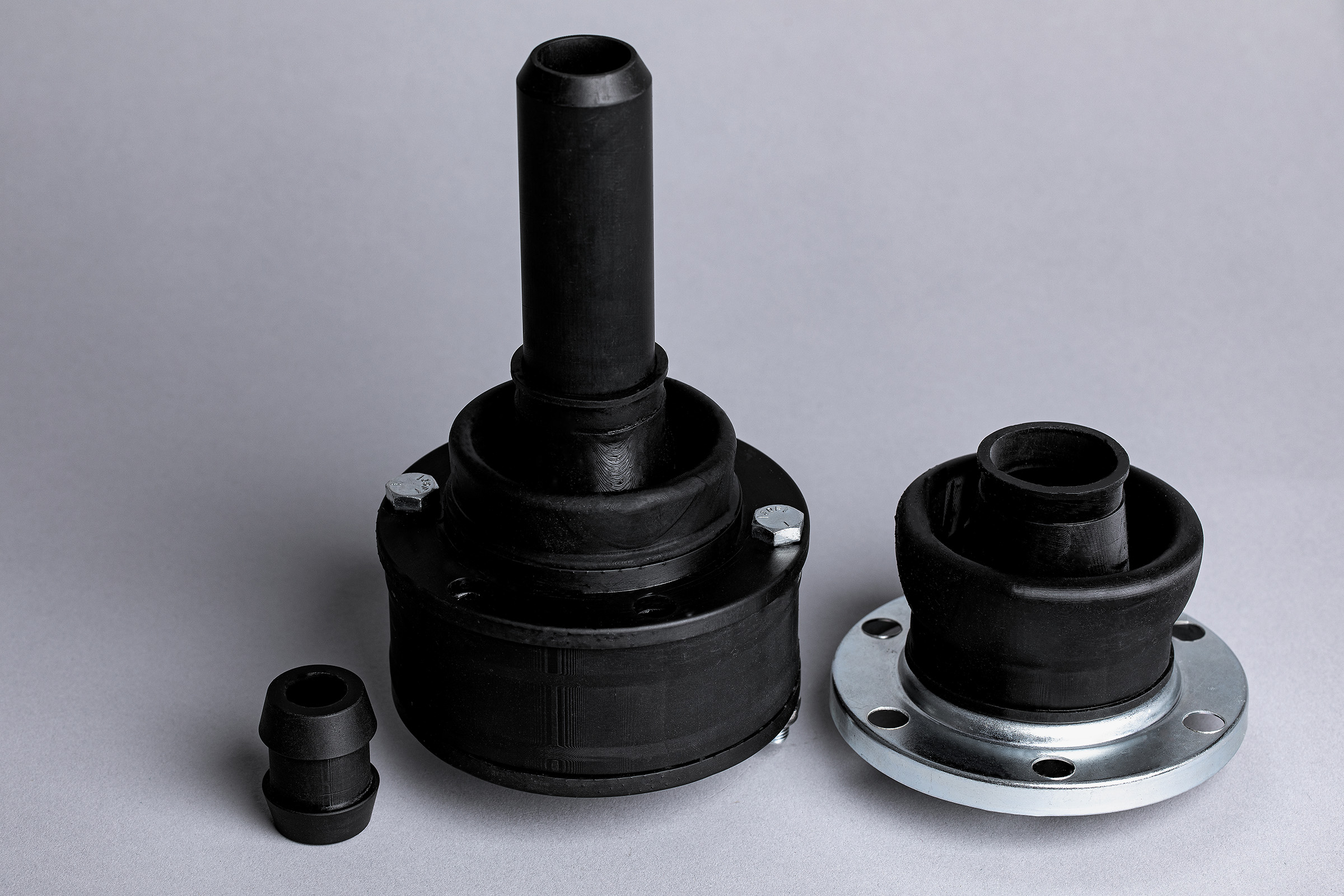

Solution Parts

3D Printing vs. Global Supply Chain Disruptions

Prior to global supply chain issues, readily available parts were accessible

through retail channels. Labor shortages, temporary or permanent plant closings have caused shortages or a complete lack of availability for mission critical replacement parts. 3D printing fills the gap for single or small run productions. Custom pieces can be reverse engineered to meet the needs for worn, hard to find or broken parts.

Small Scale, Small Footprint

On demand 3D manufacturing changes the way companies design, produce, plan and distribute their products. They can be competitive in their industries by continuously innovating their products; quickly filling a need without necessitating a large inventory costs and storage space.