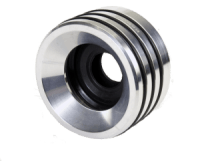

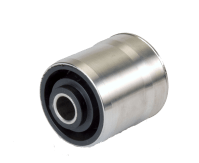

Proven Tough in Extreme Conditions

Chemical change, heat, moisture, vibration or a combination of all factors test the limits of any product. Meeting those challenges factory-side to perform the ultimate in transport, industrial and manufacturing environments sets Seals-it apart and has for 30 years.